OptiPhos® Plus trial data 2017 - 2019

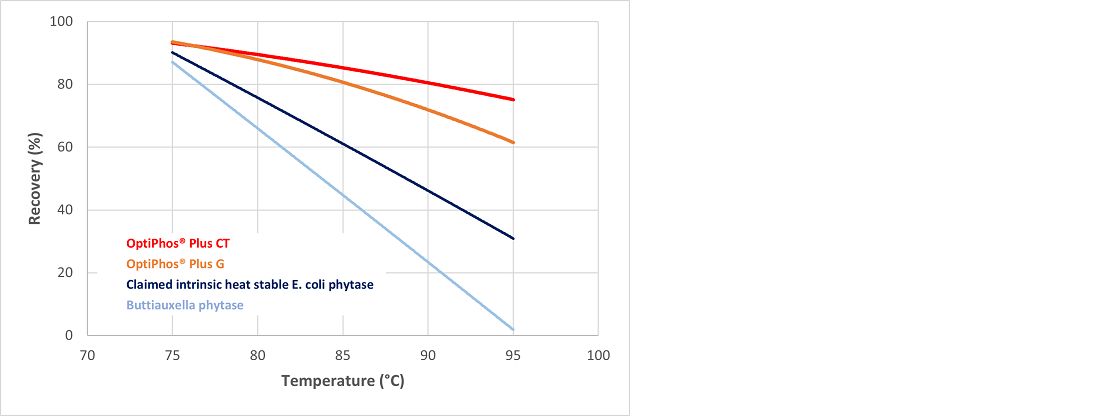

A total of 14 pelleting trials in Europe (at five different trial locations) and six in the USA (at five different locations) have been conducted with both the granular and the coated product forms. In most of these trials, competitor products were also included to compare the performance of OptiPhos® Plus against commercial standards. The most frequently used products were a Buttiauxella phytase, and a claimed intrinsically heat stable E. coli phytase expressed in Trichoderma reesei. The large number of trial locations provided a wide variety of pelleting and operating conditions, mimicking the real situation in the field.

All data from these pelleting studies were plotted on a graph, and the best fitting curve drawn (Figure 1). OptiPhos® Plus outperformed the competitor products and showed heat stability up to 85 oC for the granular (G) form and up to 95 oC for the coated (CT) form.

Reconfirming the intrinsic heat stability and the value of granulation

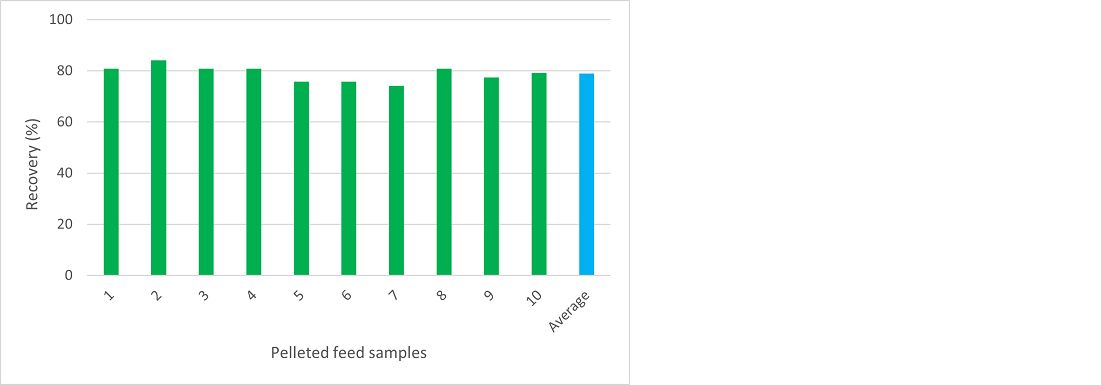

In a pelleting study conducted at a large industrial feed mill, the heat stability of OptiPhos® Plus was assessed in its pure, non-granulated powder form (concentrated powder product as it leaves the fermenter, then dried). The trial was conducted at a feed mill which is known for its harsh pelleting conditions:

- temperatures of 84 to 85 oC at the conditioner exit (so above 85 oC in the pelletizer)

- double conditioning - 128 seconds total conditioning time

The results indicated that even in these harsh conditions, OptiPhos® Plus showed an average recovery of 80% (Figure 2). This proves the high intrinsic stability of this new phytase in an industrial pelleting operation without granulation or coating technology.

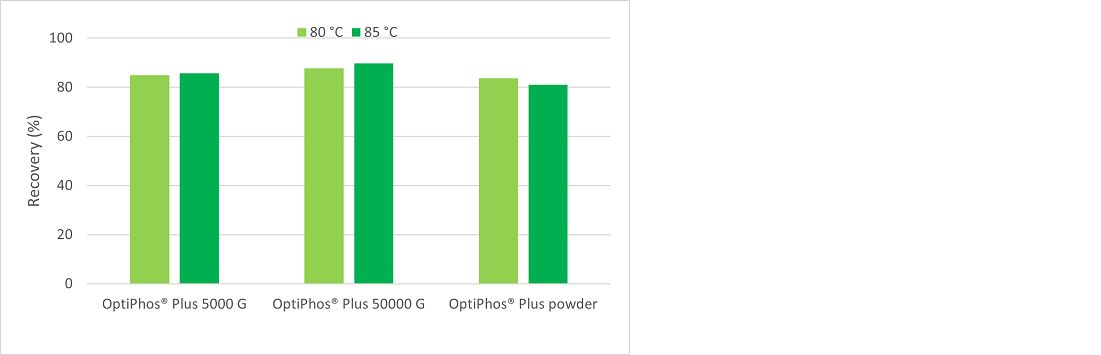

The impact of the granulation process and enzyme concentration on the heat stability of the new phytase was shown in a pelleting trial conducted in Denmark in which OptiPhos® Plus 500 G and 50000 G were compared with OptiPhos® Plus powder at 80 and 85 oC. OptiPhos® Plus G had a 2 to 4% higher recovery compared to OptiPhos® Plus powder, indicating that the microgranulation process may also aid the heat stability of OptiPhos® Plus (Figure 3).

At the same time, it was observed that the heat stability of OptiPhos® Plus 50000 G was equal to that of OptiPhos® Plus 5000 G, indicating that the phytase concentration in the granulate does not influence the thermostability of this new phytase.

The best proof: field experience

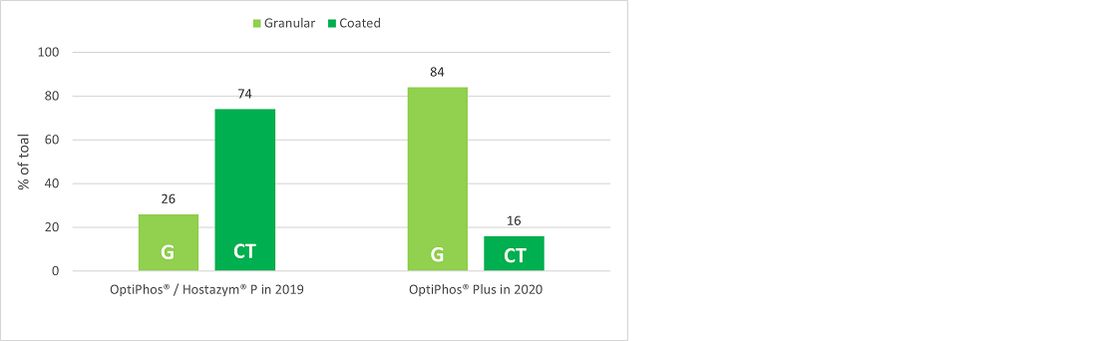

The best way to learn about the heat stability of granular OptiPhos® Plus G is to look at its sales versus the coated version (CT). Figure 4 shows the sales of OptiPhos® Plus G and CT in 2020 in those countries where OptiPhos® Plus was already registered. It can be seen that 84% of OptiPhos® Plus sales were in the G form while only 16% were in the CT form.

This information was compared to the sales of the coated OptiPhos® or Hostazym® P in 2019 in the same countries (which was replaced by OptiPhos® Plus in 2020). The data show that 26% of sales was in the granular form and 74% in the coated form.

This move from coated OptiPhos®/Hostazym® P in 2019 towards granular OptiPhos® Plus G in 2020 is the best proof that under field feed production conditions, the granular OptiPhos® Plus G has proven its thermostability.

Conclusion

Our new phytase, OptiPhos® Plus G has proven in research studies and also in field situations to show high intrinsic heat stability and is thereby the product form of choice.